When surfaces demand precision, it’s a combination of force and the right tool that sets the standard. Efficient blasting begins with choosing the correct garnet abrasive mesh size. Though many professionals instinctively reach for the widely used 30/60 grade, it’s not a one-size-fits-all solution.

Finer grains often outperform their coarser counterparts in surprising ways. Let us examine how mesh size shifts blasting performance and why, more often than not, the smallest grains carry the greatest impact.

Why Mesh Size Matters in Garnet Abrasive

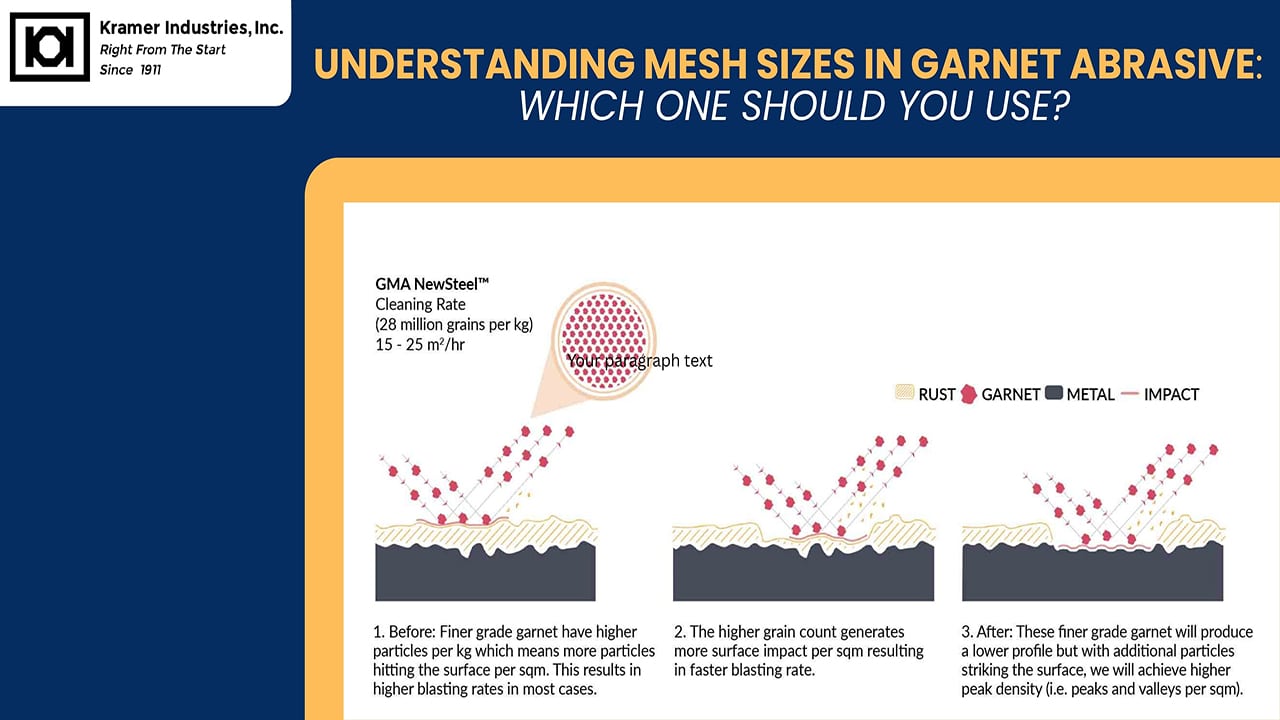

“Mesh size” may sound like a technicality, but it’s the quiet architect behind every well-prepared surface. It defines the size of each abrasive grain used in the blasting process. A single kilogram of garnet abrasive can contain anywhere from four to 13 million grains, depending on the grade. This number is a signal of how the material will behave in motion.

Coarser grains work with a strong, spaced-out force. They impact with weight, but they leave gaps. Finer grains, on the other hand, move with more hits, more coverage, and more consistency. The result is a surface that’s cleaned and truly refined.

Quick Tips for Better Blasting Results

To get the best results using garnet abrasive, make sure you:

- Choose the right grain size for your surface

- Use clean, dry compressed air at the correct pressure

- Keep your abrasive flow steady and well-regulated

These simple steps make a big difference. You’ll avoid uneven textures, wasted material, and surfaces that need rework. A smooth and consistent profile also helps paint and coatings stick better.

What Makes Garnet Abrasive Special?

Garnet abrasive is sharp enough to cut, hard enough to endure, and tough enough to keep going under pressure. Its unique combination of sharp edges and dense structure allows it to work efficiently even at lower air pressures.

The advantage is the gentler treatment of both your equipment and the surface at hand. You get powerful cleaning without any collateral damage. The controlled precision is what makes garnet stand out.

Why You Might Need a Finer Garnet Abrasive

Coarse grains make fewer hits per square foot, but they dig deeper.

Finer garnet abrasive produces more strikes in the same space, giving you:

- Higher blasting speed

- Cleaner surface finish

- A consistent surface profile

- Better performance on rust, scale, and old coatings

- The ability to reach tight spaces

It’s especially useful when you want the surface clean without leaving big grooves or rough spots.

Picking the Right Garnet Abrasive for the Job

Every job calls for a different finish. The correct grade depends on the kind of surface you’re working with and the result you want.

- 30/60 mesh is the industry standard for general jobs needing profiles over 75 microns.

- 80 to 120 mesh is finer and used for smoother finishes.

- 200 to 300 mesh is ultra-fine and great for delicate work.

Also, blasting is about cleaning it well enough for the coating to stick and last without overdoing it.

When to Use Finer Garnet Abrasive

Finer abrasive gives you more control and causes less damage. It’s ideal for:

Sweep Blasting

Used when a surface has started to corrode or when old coatings are breaking down. Fine garnet abrasive gently cleans and roughens the surface without stripping everything away, helping new coatings stick better, especially over intact paint.

Maintenance on Pitted Surfaces

If the surface is deeply pitted or has thin coatings, finer abrasive reaches into those pits better than coarse grains. This prevents coating failure caused by dirt left in the pits.

Low Dust, High Precision

Since garnet abrasive produces very little dust, finer grades are perfect when you want to avoid contaminating nearby areas—like in factories or workshops with sensitive equipment.

Specialized Uses for Finer Garnet Abrasive

Architectural Concrete

To achieve a clean, polished finish on decorative concrete, a fine garnet abrasive is a must. Coarser grains might remove too much, and once that happens, there’s no fixing it.

Aluminum and Galvanized Surfaces

These softer materials need a gentle touch. Finer garnet abrasive cleans the surface without causing dents or rough patches.

Fiberglass Repairs

When restoring fiberglass, you often need to remove just the top layer of resin without touching the gel coat. Finer grains let you feather the surface with precision.

Graffiti Removal

Because this often requires multiple passes, it’s crucial not to damage the base material. Finer garnet abrasive gives the operator more control to remove paint without digging into the surface.

Propellers and Turbines

Delicate components like turbines and propellers can be cleaned with ultra-fine garnet abrasive at low pressure. This clears debris without affecting the part’s shape or balance.

When to Use Larger Garnet Abrasive

In some cases, coarser garnet abrasive is the better choice. When you’re dealing with:

- Thick coatings over 500 microns

- Heavy rust on ship hulls

- Tough, rubbery coatings

…you need a more aggressive impact. The larger grains hit harder and remove thick material faster.

Conclusion

Fine or coarse—each grade has its place. But for most tasks that need a clean, even finish without going too deep, finer garnet abrasive is the smarter option. It:

- Gives you cleaner profiles of up to 75 microns

- Provides better control

- Helps prevent coating failures

- Works well on rust, mill scale, low-build coatings, and delicate materials

By using just the right particle size for the job, you save time, reduce waste, and avoid costly do-overs. Less filler, fewer repairs—and a surface that’s ready for whatever comes next.

With a wide range of media, technical know-how, and decades of hands-on experience, Kramer Industries offers the perfect abrasive solution for every application. Whether you’re cleaning turbines or prepping concrete, Kramer helps you blast with confidence—and finish like a pro.