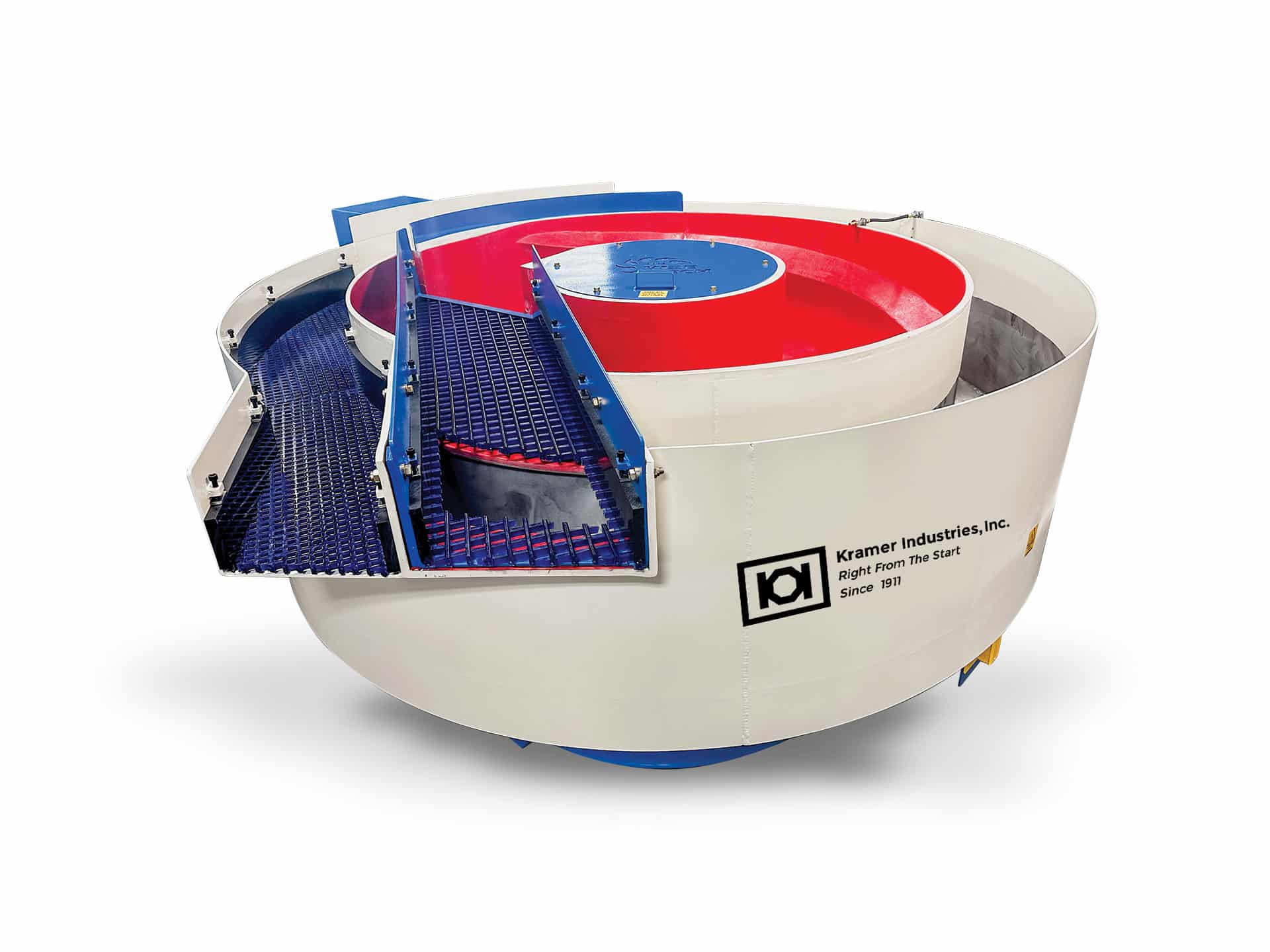

CVB Series – Vibratory Combination Finisher-Dryer

The DB Series is ideal for shorter cycle times and for those new to mass finishing. Two different sizes are available for large and small batch sizes. Economical and durable, the DB Series are one of our most popular vibratory tumblers.

Labor Efficiency. Optimized Floor Space. Lower Total Cost.

Kramer’s CVB Series vibratory finisher systems combine two essential processes into one advanced vibratory finishing machine. By integrating vibratory finishing and drying into a single vibratory finishing system, these machines reduce part handling, save floor space, and lower overall operating costs.

Designed for manufacturers seeking the best vibratory finisher solution for high-throughput environments, CVB systems deliver consistent results while minimizing transfer points and improving production efficiency.

Overview

CVB Series vibratory finisher dryers are engineered to finish and dry parts continuously within one compact unit. Finished components are internally separated from the media and automatically transferred into an outer drying channel, where controlled heat and media action provide effective drying and light polishing.

This integrated vibratory finisher dryer design improves workflow efficiency and eliminates the need for separate machines. CVB systems are available in standard radius and long radius configurations, allowing the vibratory finishing machine to be matched precisely to part geometry, material, and production volume.

Adjustable amplitude, lead angle settings, optional variable frequency drives, and a broad range of media and compound options make the CVB Series vibratory finisher suitable for nearly any mass finishing application.

Typical applications include deburring heavy stampings, radiusing laser-cut parts, polishing machined components, ball burnishing, surface smoothing, and drying heat-treated or wet-processed parts using a built-in vibratory dryer channel.

Standard Radius CVB Series

Standard radius CVB models provide a versatile solution for manufacturers requiring reliable vibratory finishing and drying performance. These machines deliver controlled, consistent action for deburring, surface smoothing, and polishing across a wide range of part sizes.

The integrated vibratory dryer channel supports continuous operation and can also be configured for batch processing, making the CVB Series vibratory finisher ideal for job shops and mixed-production environments.

Long Radius CVB Series

Long radius CVB models feature an extended working channel and larger bowl diameter to deliver more aggressive finishing action. This configuration increases part travel time and energy input, making it ideal for demanding applications.

These machines are commonly selected as the best vibratory finisher option for heavy deburring, edge radiusing, grinding, polishing, and ball burnishing of stampings, castings, forgings, and machined components within a fully integrated vibratory finishing system.

Key Features

- Heavy-duty welded steel construction

- Premium polyurethane lining for long service life

- Extra-large isolation springs for durability

- Exterior-mounted components for simplified maintenance

- Single drive system and unified electrical panel

- Wide range of custom options available

- Designed and built in the USA

Advantages

- One vibratory finishing machine performs finishing and drying

- Reduced footprint compared to separate machines

- Less part handling improves labor efficiency

- High production capability supports cost reduction

- Simplified maintenance with a single drive system

- Bottom-heated vibratory finisher dryer distributes heat evenly

Results

With a compact footprint, flexible configurations, and robust construction, the CVB Series vibratory finisher delivers measurable improvements in productivity, consistency, and operating efficiency. Whether installed as a standalone vibratory finishing machine or integrated into an automated vibratory finishing system, CVB machines provide a scalable, long-term solution for modern manufacturing operations.

Specifications

Standard Radius CVB Series |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

CVB Model |

Bowl Diameter |

Finish Channel Width |

Dryer Channel Width |

Floor Space Required (w/o Panel) |

Finish Working Capacity (Cu Ft) |

Dryer Working Capacity (Cu Ft) |

Motor HP |

Full Load Amps @ 480V |

Water Pump Used (GPH) |

Air Supply Required |

CVB-150 |

40″ | 7.5″ | 6″ | 4′ × 4′ | 1.5 | 1.5 | 2 | 3 | 4 | 100 psi** |

CVB-380 |

50″ | 9.5″ | 6″ | 5′ × 5′ | 3.8 | 2 | 3 | 4 | 8 | 100 psi** |

CVB-700 |

60″ | 11″ | 8″ | 6′ × 6′ | 7 | 5 | 5 | 6 | 14 | 100 psi** |

CVB-950 |

71″ | 13.5″ | 8″ | 7′ × 7′ | 9.5 | 7 | 7.5 | 10 | 20 | 100 psi** |

CVB-1300 |

80″ | 15″ | 10″ | 8′ × 8′ | 13 | 10 | 7.5 | 10 | 25 | 100 psi** |

CVB-1900 |

88″ | 17″ | 10″ | 9′ × 9′ | 19 | 14 | 15 | 20 | 40 | 100 psi |

CVB-2400 |

96″ | 19″ | 12″ | 10′ × 10′ | 24 | 17 | 15 | 20 | 50 | 100 psi |

**Applicable if optional Pneumatic Gate is purchased

Long Radius CVB Series |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

CVB Model |

Bowl Diameter |

Finish Channel Width |

Dryer Channel Width |

Floor Space Required (w/o Panel) |

Finish Working Capacity (1/3 Fill Rise) (Cu Ft) |

Finisher Working Capacity (Full Rise) |

Dryer Working Capacity (Cu Ft) |

Motor HP |

Full Load Amps @ 480V |

Water Pump Used (GPH) |

Air Supply Required |

CVB-250 |

56″ | 7.5″ | 6″ | 6′ × 6′ | 2.5 | 2 | 2 | 3 | 4 | 5 | 100 psi** |

CVB-500 |

67″ | 9.5″ | 6″ | 7′ × 7′ | 5 | 4 | 3 | 5 | 6 | 10 | 100 psi** |

CVB-1000 |

82″ | 11″ | 8″ | 9′ × 9′ | 10 | 8 | 7 | 7.5 | 10 | 15 | 100 psi** |

CVB-2000 |

112″ | 13″ | 10″ | 11′ × 11′ | 20 | 16 | 14 | 20 | 27 | 30 | 120 psi |

CVB-3000 |

136″ | 15″ | 10″ | 13′ × 13′ | 30 | 26 | 20 | 20 | 27 | 45 | 120 psi |

**Applicable if optional Pneumatic Gate is purchased

CVB-2400 Combo Finisher

CVB Series Double

Related Products

-

Plastic Tumbling Media

$3.27Plastic Tumbling Media is recommended for general purpose metal removal, pre-plate finishing, and moderate cutting. Plastic Tumbling Media is ideal for soft metals such as brass and aluminum or for stringy materials to avoid rolling the burr into a hole.

-

Liquid Burnishing Compounds

Price range: $39.95 through $139.75 The range of Liquid Finishing Compounds for mass finishing are used in all types of tumbling. All are pH balanced and concentrated for optimal performance. Safe to use with all tumbling media types.

The range of Liquid Finishing Compounds for mass finishing are used in all types of tumbling. All are pH balanced and concentrated for optimal performance. Safe to use with all tumbling media types. -

MB Series – Heavy-Duty Grade, Mini-Bowl Style, Vibratory

$729.00The MB Series is ideal for shorter cycle times and small batch runs. Economical and durable, the MB Series are great ?starter? systems for those looking to get into mass finishing or need a unit for scale-up testing. Some systems can be upgraded for use with steel tumbling media.

-

EV Series – Heavy-Duty Grade, Tub-Style, Floor Model, Vibratory Tumbler

$12,995.00 The EV Series is engineered for production environments and heavy usage. Multiple sizes are available with customizable sizes commonly manufactured. One of the most heavy duty vibratory systems available.

The EV Series is engineered for production environments and heavy usage. Multiple sizes are available with customizable sizes commonly manufactured. One of the most heavy duty vibratory systems available.